Infrared Water-in-Oil Online Sensor (IR Water Control)

Have you ever experienced a too early oil exchange due to water issues? With this sensor which is monitoring water in oil 24/7 in real time, you will be able to take the necessary steps, before expensive overhauls will have to be done. The infrared transmission principle enables the operator to monitor the water content in lubricants with a reliable and accurate way like:

-

- Crankcase Oils of Crosshead Engines

- Thermal Oils

- Oil-Lubricated Stern-Tube Seals

- Hydraulic Oils

- Gear Oils

This sensor is the start for a wide range of sensors covering the most important parameters of lubricants to help the operators get instant information about the condition of the lubricants onboard.

TRIBOMAR is constantly developing new systems in the segment of sensor technology to follow up with the latest innovations in the market.

Features

-

- Infrared Water-in-Oil (WiO) Online Sensor for Lubricants

- 24/7 Online monitoring during operation

- Perfect tradeline of even very low range values

- Using onshore laboratory methods

- Precise determination of water content of mineral oils

- Easy to install bypass

- High accuracy due to automated soot correction

- Free of maintenance and re-calibration

- Fully confirmed with newest European Directives

- Results directly shown on display

Specifications

-

- Two Measuring range: 0 – 1,0 % or 0 – 10.000 ppm

- Oil temperature range: 20 – 80° C max.

- Operation pressure: 10 bar max.

- Accuracy: +/- 5%

- Measures: 1. Saturated, 2. Emulsified and 3. Free water

- Individual alarm settings

- Storage backup Online and via SD-card

Order No.: #1117, Infrared Water-in-Oil Online Sensor (IR Water Control)

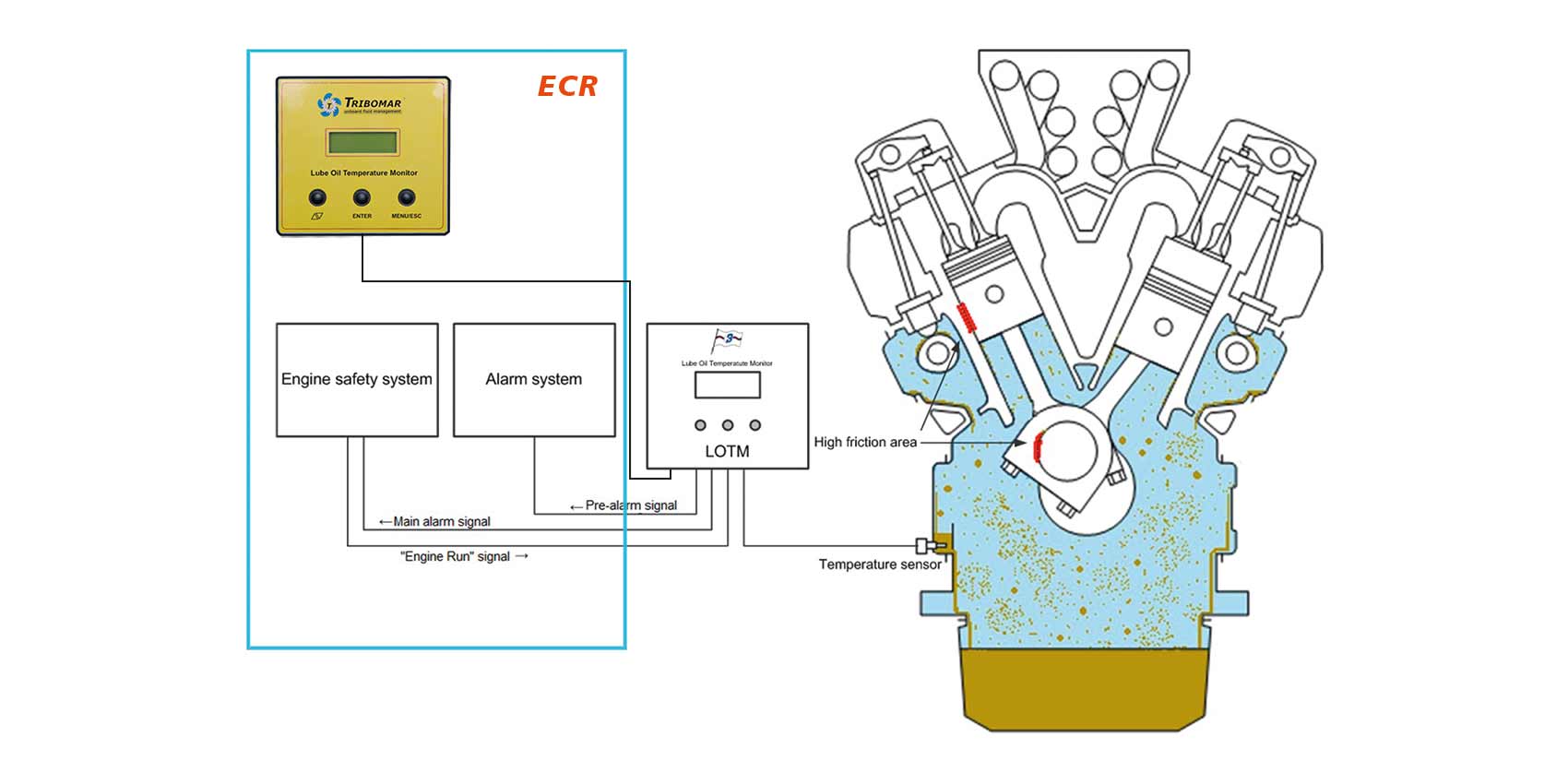

Lube Oil Temperature Monitor (LOTM)

Have you had an engine slow down false alarm due to oil mist? In older engines no reliable alarm systems are installed. That is why we introduced the Lube Oil Temperature Monitor (LOTM). It is designed to protect the crankshaft as well as other sliding metallic surfaces on marine diesel engines using the early prediction of severe damage.

The circulating lube oil comes out from the rotating components and splashes on the crankcase inner walls and crankcase covers.

On the crankcase covers there are special catch pockets with mounted temperature sensors. The current temperature values are constantly measured and processed by a microcontroller.

The microcontroller of the LOTM calculates the mean temperature and compares each station temperature value with permissible deviation value and maximum permissible temperature. In case of an abnormal temperature deviation the LOTM switches on an alarm signal which is transmitted to the connected ship alarm system.

Lube Oil Temperature Monitor (LOTM)

-

- Oil temperature monitoring in crankcases

- Protects your engine from severe damage

- Simple principle with high valuable output

- GL approval

Order No.: #1095, Lube Oil Temperature Monitor (LOTM)