Suction Type Gas Detectors

PS-7 Series Single Channel Gas Detector

PS-7 – Single channel gas detector

A suction type detector for indoor use. Sensor units are factory calibrated and delivered to site ready for use.

Optional communication module for DeviceNet interface or PoE, ModBus/TCP.

- Sensor units are already calibrated when delivered to the site. Sensor units only need zero check and operation checks after being replaced, and they are ready to monitor gas concentration.

- Used sensor units are returned when obtaining new ones so they can be recycled.

- Sensor units and gas flow path can be replaced without tools.

- All functional parts are in modules for easy replacement.

- The Cosmos assists in reliable management of the timing for sensor unit and gas flow path replacement.

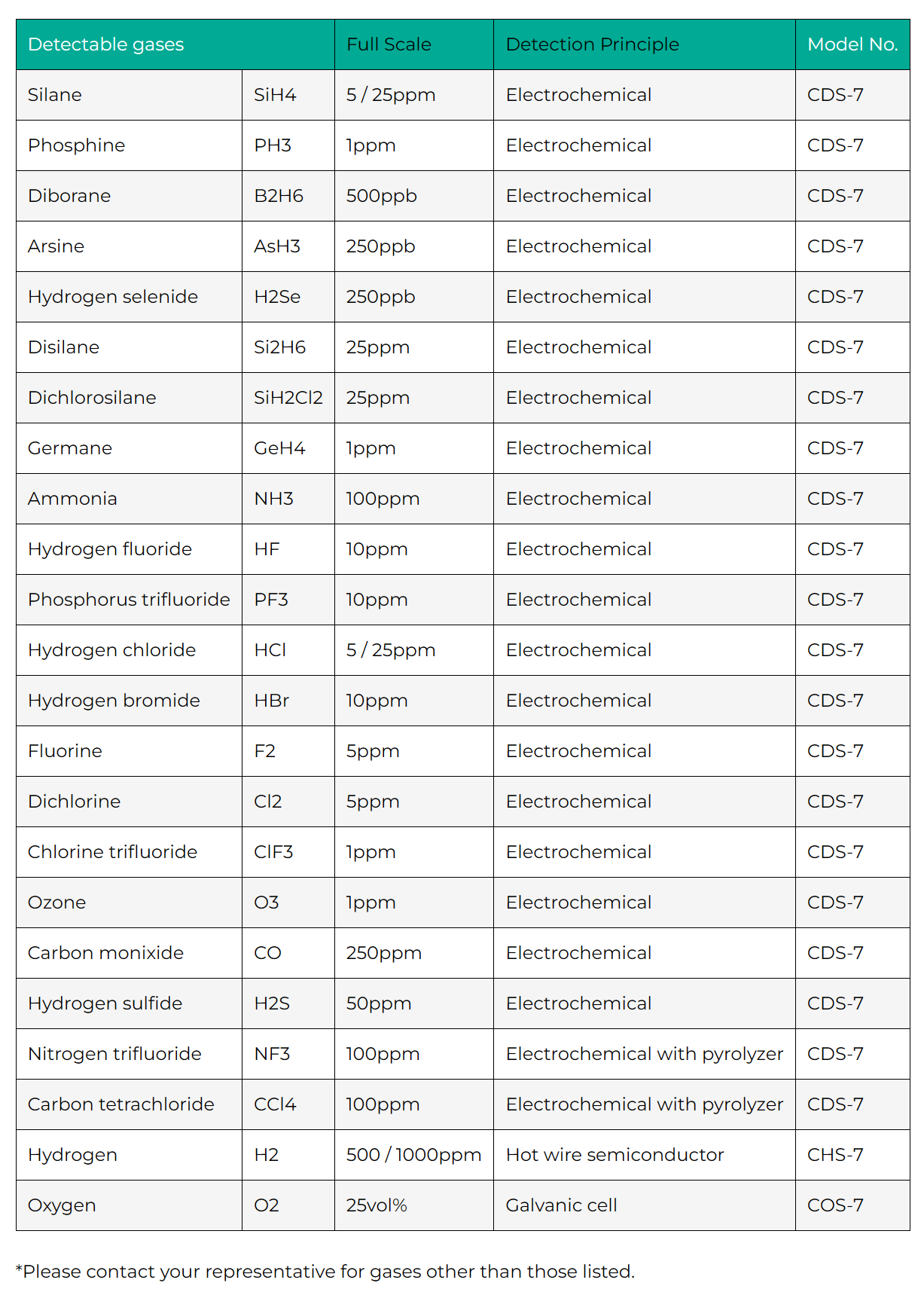

Detectable gases:

| Model | PS-7 | |

|---|---|---|

| Standard Type | With a Pyrolyzer | |

| Detection Principle | Electrochemical cell, Hot wire semiconductor, Galvanic cell | Pyrolysis + Electrochemical cell |

| Sampling Method | Extractive type (Sample flow rate: 0.5L/min, automatic control) | |

| Sampling Tubing*1 | Teflon – External diameter: 6mm, Internal diameter: 4mm, Tubing length: 20m or less | |

| Gas Concentration Indication | 4-digit LCD (with measuring unit), 20 – step bar graph | |

| Alarm Indication | Gas alarm (1st and 2nd atage) | |

| – Alarm: Red LED lamp flashing | ||

| LCD – ALARM1 for 1st stage, ALARM1 and ALARM2 for 2nd stage | ||

| Low flow alarm | ||

| – Clogging indication: LCD – Flow sign rotates slowly | ||

| – Alarm: Yellow LED lamp flashing | ||

| LCD – FLOW indication, Flow sign stops rotating | ||

| Sensor trouble alarm/Incorrect sennsor insertion alarm | ||

| – Alarm: Yellow LED lamp flashing | ||

| LCD – SENS. indication | ||

| Pyrolyzer wire break alarm*2 | ||

| – Alarm: Yellow LED lamp flashing | ||

| LCD – CONV. indication | ||

| External Output | – Gas concentration analog output: 4-20 mADC (shared with the power source | |

| negative terminal) | ||

| – Gas alarm contact (1st and 2nd stage): 1a no-voltage contact/Non-latching | ||

| – Trouble alarm contact (Open collector/Non-latching) | ||

| Application Cable | 3C or 4C shielded control cable (φ8-11mm) x 2 | |

| Operating Temperature | 0 to 40 °C (No sudden change) | |

| / Humidity | 30 to 85 %RH (No condensation) | |

| Power Source | 24 VDC ±10% | |

| Power Consumption | Approx. 7W | |

| Dimensions | W62 X H124 X D143 mm (excluding options and protrusions) | |

| Weight | Approx. 1.0kg | |

| Installation | Wall mount | |

| Approval | CE, SEMI (Semiconductor Equipment and Material Standard) | |

*1 Teflon is recommended. But it depends on operating conditions when the gas adsorption capacity is high, so contact us for more information. The specifications above are subject to change without prior notice.

*2 Only for the model with a pyrolyzer.

CE Declaration of Conformity

SH-WAD Series Single Channel Gas Detector

Reliable and well proven

The SH-WAD range gas detectors have become the standard safety solutions for many production facilities and research centres. They are not only used in cleanrooms but also very useful in many other hazardous environments. The SH-WAD gas detectors can be equipped with universal plug-in modules for the provision of additional functions and communication protocols.

All units comply with the most stringent quality standards and are extremely reliable. With the integrated self diagnostics functions you are quickly notified on any possible disruption. In-Control Software will provide access to additional information about any changes in the status of the unit. By using an overall data-acquisition and monitoring system like SIMS-NX it is even possible to monitor the status of all detectors real-time. In this way there will never be a lack of clarity or information in case of an event.

There are 2 models in the SH-1000-WAD series:

- SH-1003-WAD

- SH-1007-WAD including pyrolyzer

/CDS sensor option: The SH-WAD series detectors are fitted with the ease of use cartridge type (CDS-7/CLS-7/CHS-7/COS-7) sensors. Other options available on request.

Maximum security and clear information

Obviously the presence of gas must be detected accurately whilst the gas sensor should be selective and preferably 100% stable! It is also important to understand that gas detection is a dynamic process – a process of gas transport and chemical and electrochemical reactions in which continuous control is essential. Managing this process requires continuous monitoring of the flow and if required the status of the pyrolyzer! Moreover, all systems permanently analyse the sensor operation.

Simple installation and configuration

Because of it’s modular construction the SH-WAD can be installed progressively.

For example, a JC-Box can be mounted during an early stage of the installation.

Configuring of the WAD units is quite simple. When installing a gas sensor, parameters such as target gas, measurement range and measurement unit are all set automatically. The user only has to specify the alarm values and the desired alarm responses. This can easily be done with the In-control™ configuration software. A laptop with this software can be connected to the RJ-45 port on the frontside of the unit.

Extensive communication possibilities

The SH-WAD unit can be used as independent detector, but can also be part of a larger gas monitoring system. Depending on the selected configuration, data transfer can take place via a bus line, but also via a 4-20mA signal. The Profibus-DP module makes it very easy to link the unit to a PLC based alarm system. Such a system offers a great deal of flexibility and minimises installation costs.

Integrated alarm handling

In practice, alarm actions are frequently desired directly at the point of detection. Using the optional relay card, an alarm output can be made available directly inside the SH-WAD unit. In many cases this considerably reduces the amount of cabling around the system.

- In Control configuration software

- Controllerbox for installation of relays and Modbus or ProfiBus modules.

Detectable gases:

- Acetic Acid, CH3COOH

- Acetonitrile, CH3CN

- Acetylene, C2H2

- Ammonia, NH3

- Arsine, AsH3

- Benzene, C6H6

- Boron Bromide, BBr3

- Boron Trichloride, BCl3

- Boron Trifluoride, BF3

- Bromine, Br2

- Butadiene, C4H6

- Carbon Dioxide, CO2

- Carbon Monoxide, CO

- Chlorine, Cl2

- Chlorine Trifluoride, ClF3

- Diborane, B2H6

- Dichlorosilane (DCS), SiH2Cl2

- Digermane, Ge2H6

- Dimethylamine (DMA), C2H7N

- Disilane, Si2H6

- Ethanol (Anhydrous), C2H5OH

- Ethylene, C2H4

- Ethylenediamine, C2H8N2

- Fluorine, F2

- Formaldehyde, HCHO

- General Acid, Gen.Acid

- Germane, GeH4

- Hydride, Hydride

- Hydrogen, H2

- Hydrogen Bromide, HBr

- Hydrogen Chloride, HCl

- Hydrogen Cyanide, HCN

- Hydrogen Fluoride, HF

- Hydrogen Selenide, H2Se

- Hydrogen Sulfide, H2S

- Iodine, I2

- Isopropyl Alcohol, IPA

- LTO520, LTO520

- Methane, CH4

- Methanol, CH3OH

- Nitric Acid,HNO3

- Nitric Oxide, NO

- Nitrogen Dioxide, NO2

- Nitrogen trifluoride, NF3

- N-Methylpyrrolidone, NMP

- Oxygen, O2

- Ozone, O3

- Phosgene, COCl2

- Phosphine, PH3

- Phosphorus Oxychloride, POCl3

- Propane, C3H8

- Propylene, C3H6

- Silane, SiH4

- Sulfur Dioxide, SO2

- Sulfur Hexafluoride, SF6

- Tetrachlorosilane, SiCl4

- Tetraethyl Silicate, TEOS

- Trichlorosilane, SiHCl3

- Trimethyl Borate (TMB), C3H9O3B

- Trimethylsilane, C3H10Si

- VCM, C2H3Cl

- Volatile Organic Compounds, VOC

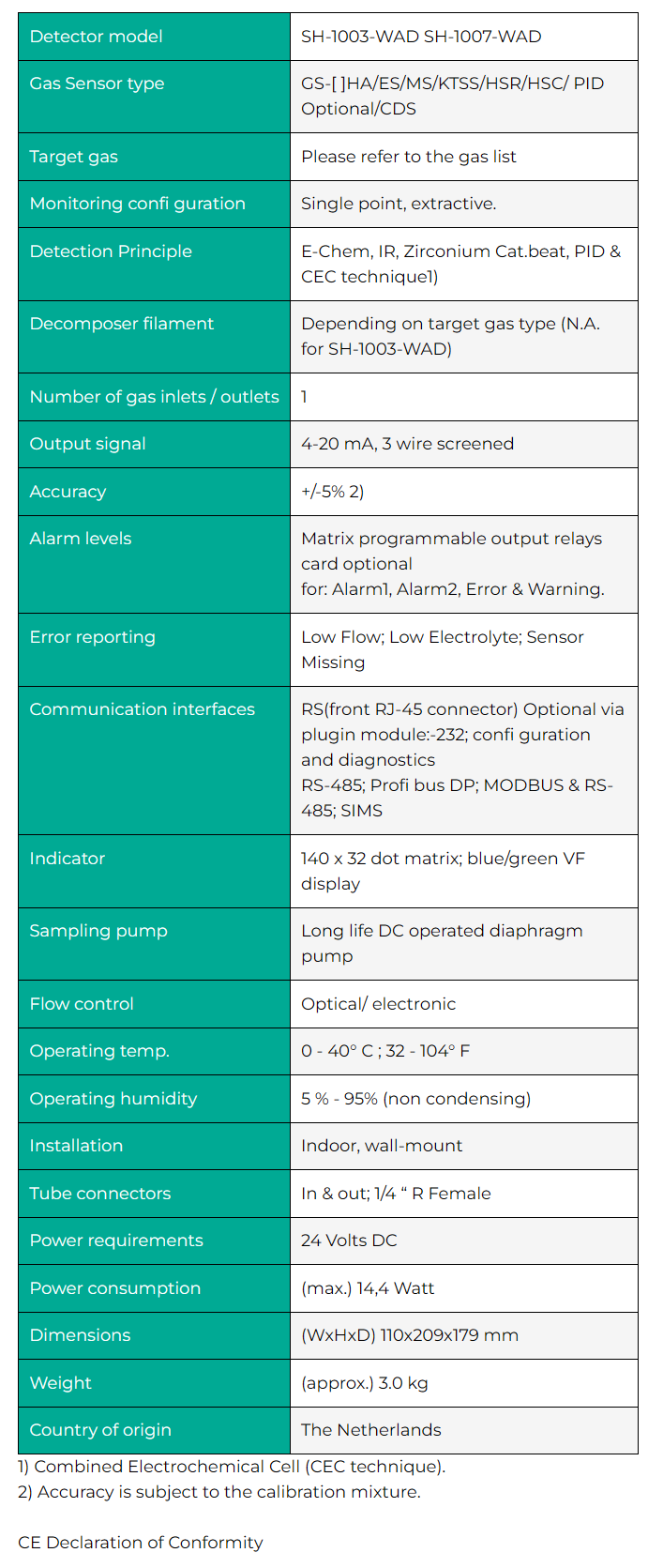

| Detector model | SH-1003-WAD SH-1007-WAD |

|---|---|

| Gas Sensor type | GS-[ ]HA/ES/MS/KTSS/HSR/HSC/ PID Optional/CDS |

| Target gas | Please refer to the gas list |

| Monitoring confi guration | Single point, extractive. |

| Detection Principle | E-Chem, IR, Zirconium Cat.beat, PID & CEC technique1) |

| Decomposer filament | Depending on target gas type (N.A. for SH-1003-WAD) |

| Number of gas inlets / outlets | 1 |

| Output signal | 4-20 mA, 3 wire screened |

| Accuracy | +/-5% 2) |

| Alarm levels | Matrix programmable output relays card optional for: Alarm1, Alarm2, Error & Warning. |

| Error reporting | Low Flow; Low Electrolyte; Sensor Missing |

| Communication interfaces | RS(front RJ-45 connector) Optional via plugin module:-232; confi guration and diagnostics RS-485; Profi bus DP; MODBUS & RS-485; SIMS |

| Indicator | 140 x 32 dot matrix; blue/green VF display |

| Sampling pump | Long life DC operated diaphragm pump |

| Flow control | Optical/ electronic |

| Operating temp. | 0 – 40° C ; 32 – 104° F |

| Operating humidity | 5 % – 95% (non condensing) |

| Installation | Indoor, wall-mount |

| Tube connectors | In & out; 1/4 “ R Female |

| Power requirements | 24 Volts DC |

| Power consumption | (max.) 14,4 Watt |

| Dimensions | (WxHxD) 110x209x179 mm |

| Weight | (approx.) 3.0 kg |

| Country of origin | The Netherlands |

1) Combined Electrochemical Cell (CEC technique).

2) Accuracy is subject to the calibration mixture.

CE Declaration of Conformity

SH-WAD Series Multi Channel Gas Detector

Reliable and well proven

The SH-WAD range gas detectors have become the standard safety solutions for many production facilities and research centres. They are not only used in cleanrooms but also very useful in many other hazardous environments. The SH-WAD gas detectors can be equipped with universal plug-in modules for the provision of additional functions and communication protocols.

All units comply with the most stringent quality standards and are extremely reliable. With the integrated self diagnostics functions you are quickly notified on any possible disruption. In-Control Software will provide access to additional information about any changes in the status of the unit. By using an overall data-acquisition and monitoring system like SIMS-NX it is even possible to monitor the status of all detectors real-time. In this way there will never be a lack of clarity or information in case of an event.

There are several models in the SH-2000-WAD and SH-4000-WAD series:

- SH-2001-WAD (up to 2 sensors with 1 pump)

- SH-2002-WAD (up to 2 sensors with 2 pumps)

- SH-4001-WAD (up to 4 sensors with 1 pump)

- SH-4002-WAD (up to 4 sensors with 2 pumps)

- SH-4004-WAD (up to 4 sensors with 4 pumps)

/CDS sensor option: The SH-WAD series detectors are fitted with the ease of use cartridge type (CDS-7/CLS-7/CHS-7/COS-7) sensors. Other options available on request.

Single pump units are normally used for applications where in one location multiple gases need to detected such as in tools and VMB’s

Multi pump units are normally used for applications where in multiple locations single gases need to be detected such as in gas cabinets. A SH-4004-WAD detector can monitor up to 4 single gas cabinets even if the gases in each cabinet are different.

By using the multi channel SH-WAD series significant cost reduction can be achieved because of less installation cost, but also because the multi channels detectors only use single processors and relay functions.

Maximum security and clear information

Obviously the presence of gas must be detected accurately whilst the gas sensor should be selective and preferably 100% stable! It is also important to understand that gas detection is a dynamic process – a process of gas transport and chemical and electrochemical reactions in which continuous control is essential. Managing this process requires continuous monitoring of the flow and if required the status of the pyrolyzer! Moreover, all systems permanently analyse the sensor operation.

Simple installation and configuration

Because of it’s modular construction the SH-WAD can be installed progressively.

For example, a JC-Box can be mounted during an early stage of the installation.

Configuring of the WAD units is quite simple. When installing a gas sensor, parameters such as target gas, measurement range and measurement unit are all set automatically. The user only has to specify the alarm values and the desired alarm responses. This can easily be done with the In-control™ configuration software. A laptop with this software can be connected to the RJ-45 port on the frontside of the unit.

Extensive communication possibilities

The SH-WAD unit can be used as independent detector, but can also be part of a larger gas monitoring system. Depending on the selected configuration, data transfer can take place via a bus line, but also via a 4-20mA signal. The Profibus-DP module makes it very easy to link the unit to a PLC based alarm system. Such a system

offers a great deal of flexibility and minimises installation costs.

Integrated alarm handling

In practice, alarm actions are frequently desired directly at the point of detection. Using the optional relay card, an alarm output can be made available directly inside WAD unit. In many cases this considerably reduces the amount of cabling around the system.

- In Control configuration software

Detectable gases:

- Acetic Acid, CH3COOH

- Acetonitrile, CH3CN

- Acetylene, C2H2

- Ammonia, NH3

- Arsine, AsH3

- Benzene, C6H6

- Boron Bromide, BBr3

- Boron Trichloride, BCl3

- Boron Trifluoride, BF3

- Bromine, Br2

- Butadiene, C4H6

- Carbon Dioxide, CO2

- Carbon Monoxide, CO

- Chlorine, Cl2

- Chlorine Trifluoride, ClF3

- Diborane, B2H6

- Dichlorosilane (DCS), SiH2Cl2

- Digermane, Ge2H6

- Dimethylamine (DMA), C2H7N

- Disilane, Si2H6

- Ethanol (Anhydrous), C2H5OH

- Ethylene, C2H4

- Ethylenediamine, C2H8N2

- Fluorine, F2

- Formaldehyde, HCHO

- General Acid, Gen.Acid

- Germane, GeH4

- Hydride, Hydride

- Hydrogen, H2

- Hydrogen Bromide, HBr

- Hydrogen Chloride, HCl

- Hydrogen Cyanide, HCN

- Hydrogen Fluoride, HF

- Hydrogen Selenide, H2Se

- Hydrogen Sulfide, H2S

- Iodine, I2

- Isopropyl Alcohol, IPA

- LTO520, LTO520

- Methane, CH4

- Methanol, CH3OH

- Nitric Acid,HNO3

- Nitric Oxide, NO

- Nitrogen Dioxide, NO2

- Nitrogen trifluoride, NF3

- N-Methylpyrrolidone, NMP

- Oxygen, O2

- Ozone, O3

- Phosgene, COCl2

- Phosphine, PH3

- Phosphorus Oxychloride, POCl3

- Propane, C3H8

- Propylene, C3H6

- Silane, SiH4

- Sulfur Dioxide, SO2

- Sulfur Hexafluoride, SF6

- Tetrachlorosilane, SiCl4

- Tetraethyl Silicate, TEOS

- Trichlorosilane, SiHCl3

- Trimethyl Borate (TMB), C3H9O3B

- Trimethylsilane, C3H10Si

- VCM, C2H3Cl

- Volatile Organic Compounds, VOC

| Detector model | SH-2001-WAD | SH-2002-WAD | SH-4001-WAD | SH-4002-WAD | SH-4004-WAD |

|---|---|---|---|---|---|

| Gas Sensor type | GS-[ ]HA/ES/MS/KTSS/HSR/HSC/ PID Optional | ||||

| Target gas | Please refer to the gas list | ||||

| Monitoring confi guration | Single point, extractive. Maximum two (2) sensors in line. | Two (2) individual single points, extractive. Maximum two (2) individual sensors. | Single point, extractive. Maximum four (4) sensors in line. | Two times single point, extractive. Maximum two times two sensors in line. | Continuous of four (4) individual single points, extractive. Maximum four (4) individual sensors. |

| Detection Principle | E-Chem, IR, Zirconium Cat.beat, PID & CEC technique1) | ||||

| Decomposer filament | type Depending on target gas | ||||

| Number of gas inlets / outlets | 1 | 2 | 1 | 2 | 4 |

| Output signal | 2 x 4-20 mA, 3 wire screened | 4 x 4-20 mA, 3 wire screened | |||

| Accuracy | +/- 5% 2) | ||||

| Alarm levels | Matrix programmable output relays card optional for: Alarm1, Alarm2, Error & Warning. | ||||

| Error reporting | Low Flow; Low Electrolyte; Sensor Missing | ||||

| Communication interfaces | RS(front RJ-45 connector) Optional via plugin module:-232; confi guration and diagnostics RS-485; Profi bus DP; MODBUS & RS-485; SIMS | ||||

| Indicator | 140 x 32 dot matrix; blue/green VF display | ||||

| Sampling pump | Long life DC operated diaphragm pump | ||||

| Flow control | Optical/ electronic | ||||

| Operating temp. | 0 – 40° C ; 32 – 104° F | ||||

| Operating humidity | 5 % – 95% (non condensing) | ||||

| Installation | Indoor, wall-mount | ||||

| Tube connectors | In & out; 1/4 “ R Female | ||||

| Power requirements | 24 Volts DC | ||||

| Power consumption | (max.) 18 Watt | (max.) 15 Watt | (max.) 20 Watt | ||

| Dimensions | (approx.) (WxHxD) 236 x 164 x184 mm | (WxHxD) 356 x 164 x 194 mm | |||

| Weight | (approx.) 3.0 kg | (approx.) 3.2 kg | (approx.) 3.2 kg | (approx.) 4.0 kg | (approx.) 4.6 kg |

| Country of origin | The Netherlands | ||||

1) Combined Electrochemical Cell (CEC technique).

2) Accuracy is subject to the calibration mixture.

CE Declaration of Conformity

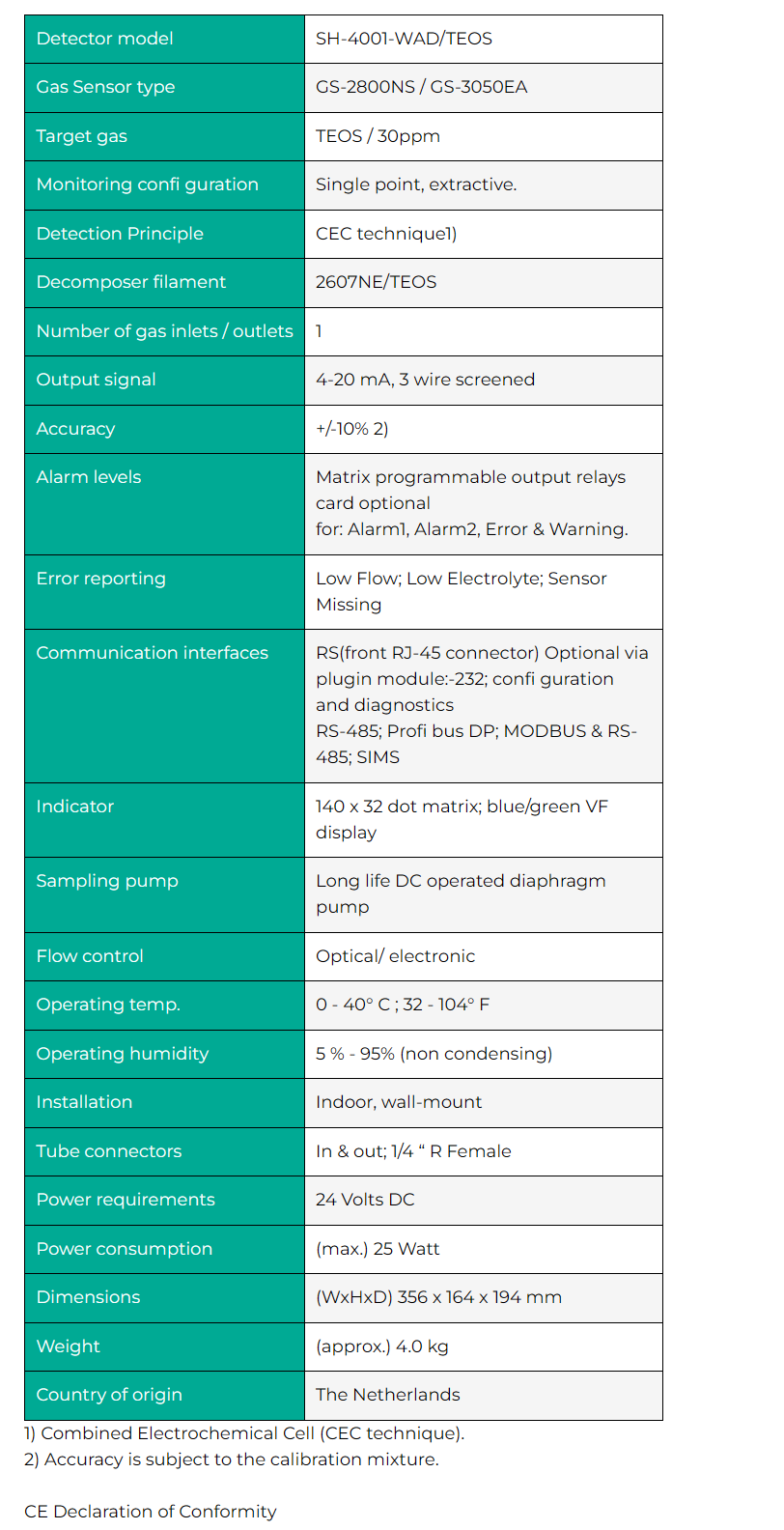

SH-WAD/TEOS Detector IPA Compensated

Reliable and well proven

The SH-WAD range gas detectors have become the standard safety solutions for many production facilities and research centres. They are not only used in cleanrooms but also very useful in many other hazardous environments. The SH-WAD gas detectors can be equipped with universal plug-in modules for the provision of additional functions and communication protocols.

All units comply with the most stringent quality standards and are extremely reliable. With the integrated self diagnostics functions you are quickly notified on any possible disruption. In-Control Software will provide access to additional information about any changes in the status of the unit. By using an overall data-acquisition and monitoring system like SIMS-NX it is even possible to monitor the status of all detectors real-time. In this way there will never be a lack of clarity or information in case of an event.

The SH-4001-WAD/TEOS gas detector is a suction type detector with two integrated sensors. Because of a smart algorithm it can see the difference between TEOS and IPA. This enables the detector to detect TEOS without interference of IPA.

- Ideal for cleanroom applications

- Integrated alarm handling

- Pyrolyzer integrated

- Optional Profibus-DP, Modbus and SIMS communication

- Data acquisition by Incontrol Software

- Possible application; Tools, Environmental, MFC box

- In Control configuration software

Detectable gases:

Tetraethyl orthosilicate Tetraethoxysilane TEOS, Si(OC2H5)4

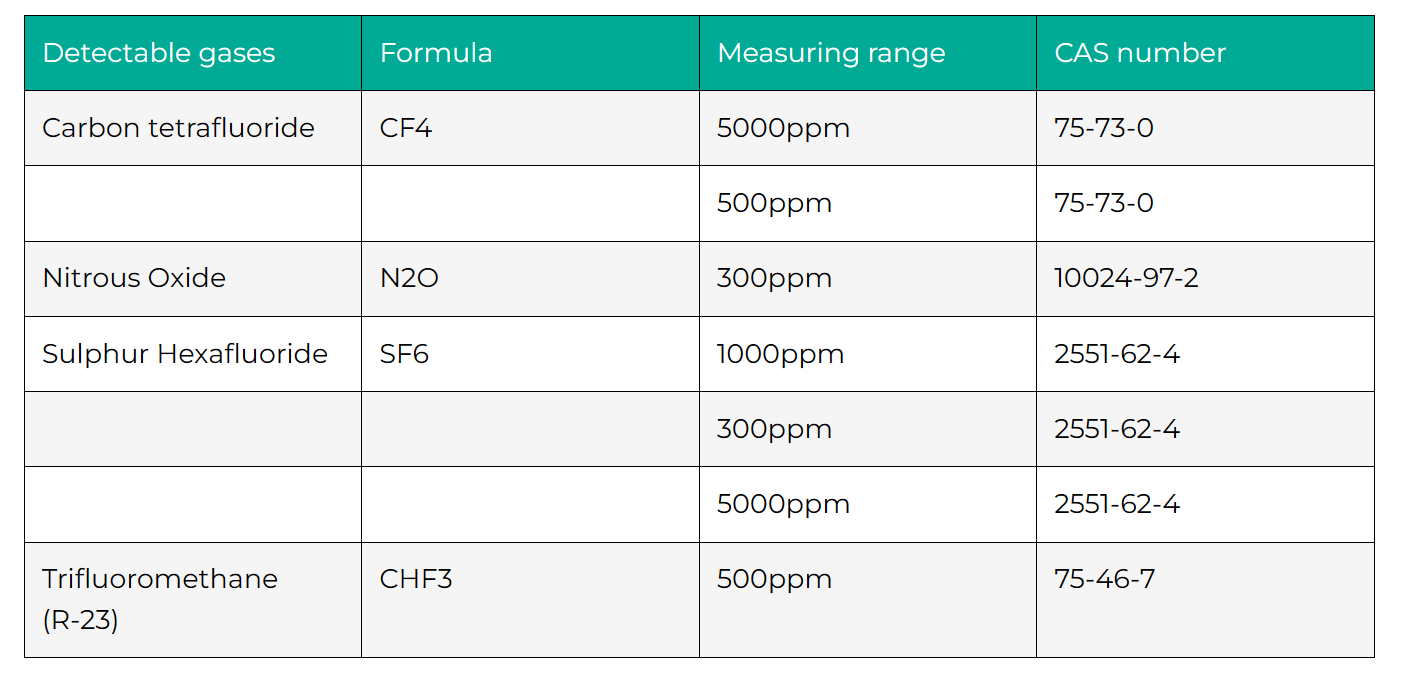

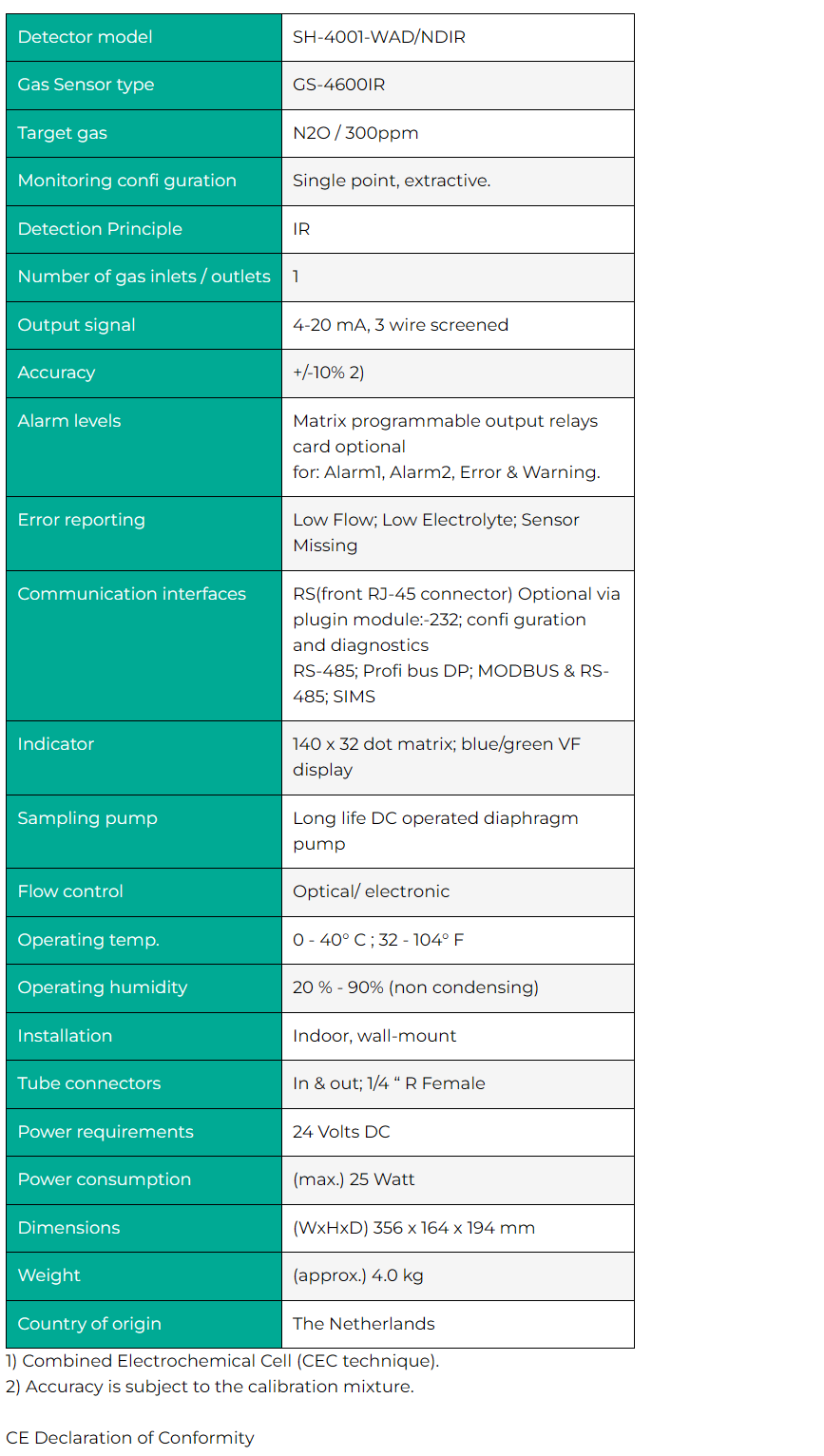

SH-WAD/NDIR Gas Detector

Reliable and well proven

The SH-WAD range gas detectors have become the standard safety solutions for many production facilities and research centres. They are not only used in cleanrooms but also very useful in many other hazardous environments. The SH-WAD gas detectors can be equipped with universal plug-in modules for the provision of additional functions and communication protocols.

All units comply with the most stringent quality standards and are extremely reliable. With the integrated self diagnostics functions you are quickly notified on any possible disruption. In-Control Software will provide access to additional information about any changes in the status of the unit. By using an overall data-acquisition and monitoring system like SIMS-NX it is even possible to monitor the status of all detectors real-time. In this way there will never be a lack of clarity or information in case of an event.

The SH-4001-WAD/NDIR gas detector is a suction type detector with a infrared (IR) type sensors. The sensor detects next to N2O Nitrous oxide at 0-300ppm other gases like sulfer hexafluride (SF6), carbon tetrafluoride CF4 or trifluoromethane (R-23) (CHF3).

- Ideal for cleanroom applications

- Integrated alarm handling

- Optional Profibus-DP, Modbus and SIMS communication

- Data acquisition by Incontrol Software

- Possible application; Tools, Environmental, MFC box

- In Control configuration software

Detectable gases:

SH-WAD/EPD Series Gas Detector for Scrubber Applications

Reliable and well proven

The SH-WAD range gas detectors have become the standard safety solutions for many production facilities and research centres. They are not only used in cleanrooms but also very useful in many other hazardous environments. The SH-WAD gas detectors can be equipped with universal plug-in modules for the provision of additional functions and communication protocols.

All units comply with the most stringent quality standards and are extremely reliable. With the integrated self diagnostics functions you are quickly notified on any possible disruption. In-Control Software will provide access to additional information about any changes in the status of the unit. By using an overall data-acquisition and monitoring system like SIMS-NX it is even possible to monitor the status of all detectors real-time. In this way there will never be a lack of clarity or information in case of an event.

For Scrubber applications the end-point of the scrubber lifetime is measured at 80-90% of the scrubber granulate. When this point is reached, the detector will give an alarm. To protect the sensor, the internal pump is timed. This means that the sample is only measured at 15% of the time. For this application this is more than enough.

There are 2 models in the SH-1000WAD series:

- SH-1003-WAD/EPD

- SH-1007-WAD/EPS including pyrolyzer

Multichannel versions are also available like the SH-2000-WAD series and the SH-4000-WAD series.

Maximum security and clear information

Obviously the presence of gas must be detected accurately whilst the gas sensor should be selective and preferably 100% stable! It is also important to understand that gas detection is a dynamic process – a process of gas transport and chemical and electrochemical reactions in which continuous control is essential. Managing this process requires continuous monitoring of the flow and if required the status of the pyrolyzer! Moreover, all systems permanently analyse the sensor operation.

Simple installation and configuration

Because of it’s modular construction the SH-WAD can be installed progressively.

For example, a JC-Box can be mounted during an early stage of the installation.

Configuring of the WAD units is quite simple. When installing a gas sensor, parameters such as target gas, measurement range and measurement unit are all set automatically. The user only has to specify the alarm values and the desired alarm responses. This can easily be done with the In-control™ configuration software. A laptop with this software can be connected to the RJ-45 port on the frontside of the unit.

Extensive communication possibilities

The SH-WAD unit can be used as independent detector, but can also be part of a larger gas monitoring system. Depending on the selected configuration, data transfer can take place via a bus line, but also via a 4-20mA signal. The Profibus-DP module makes it very easy to link the unit to a PLC based alarm system. Such a system

offers a great deal of flexibility and minimises installation costs.

Integrated alarm handling

In practice, alarm actions are frequently desired directly at the point of detection. Using the optional relay card, an alarm output can be made available directly inside WAD unit. In many cases this considerably reduces the amount of cabling around the system.

End-point detection function for scrubbers

For Scrubber applications the end-point of the scrubber lifetime is measured at 80-90% of the scrubber granulate. When this point is reached, the detector will give an alarm. To protect the sensor, the internal pump is timed. This means that the sample is only measured at 15% of the time. For this application this is more than enough.

- In Control configuration

- Controllerbox for installation of relays and Modbus or ProfiBus modules.

Detectable gases:

Detectable gases:

- Acetic Acid, CH3COOH

- Acetonitrile, CH3CN

- Acetylene, C2H2

- Ammonia, NH3

- Arsine, AsH3

- Benzene, C6H6

- Boron Bromide, BBr3

- Boron Trichloride, BCl3

- Boron Trifluoride, BF3

- Bromine, Br2

- Butadiene, C4H6

- Carbon Dioxide, CO2

- Carbon Monoxide, CO

- Chlorine, Cl2

- Chlorine Trifluoride, ClF3

- Diborane, B2H6

- Dichlorosilane (DCS), SiH2Cl2

- Digermane, Ge2H6

- Dimethylamine (DMA), C2H7N

- Disilane, Si2H6

- Ethanol (Anhydrous), C2H5OH

- Ethylene, C2H4

- Ethylenediamine, C2H8N2

- Fluorine, F2

- Formaldehyde, HCHO

- General Acid, Gen.Acid

- Germane, GeH4

- Hydride, Hydride

- Hydrogen, H2

- Hydrogen Bromide, HBr

- Hydrogen Chloride, HCl

- Hydrogen Cyanide, HCN

- Hydrogen Fluoride, HF

- Hydrogen Selenide, H2Se

- Hydrogen Sulfide, H2S

- Iodine, I2

- Isopropyl Alcohol, IPA

- LTO520, LTO520

- Methane, CH4

- Methanol, CH3OH

- Nitric Acid,HNO3

- Nitric Oxide, NO

- Nitrogen Dioxide, NO2

- Nitrogen trifluoride, NF3

- N-Methylpyrrolidone, NMP

- Oxygen, O2

- Ozone, O3

- Phosgene, COCl2

- Phosphine, PH3

- Phosphorus Oxychloride, POCl3

- Propane, C3H8

- Propylene, C3H6

- Silane, SiH4

- Sulfur Dioxide, SO2

- Sulfur Hexafluoride, SF6

- Tetrachlorosilane, SiCl4

- Tetraethyl Silicate, TEOS

- Trichlorosilane, SiHCl3

- Trimethyl Borate (TMB), C3H9O3B

- Trimethylsilane, C3H10Si

- VCM, C2H3Cl

- Volatile Organic Compounds, VOC

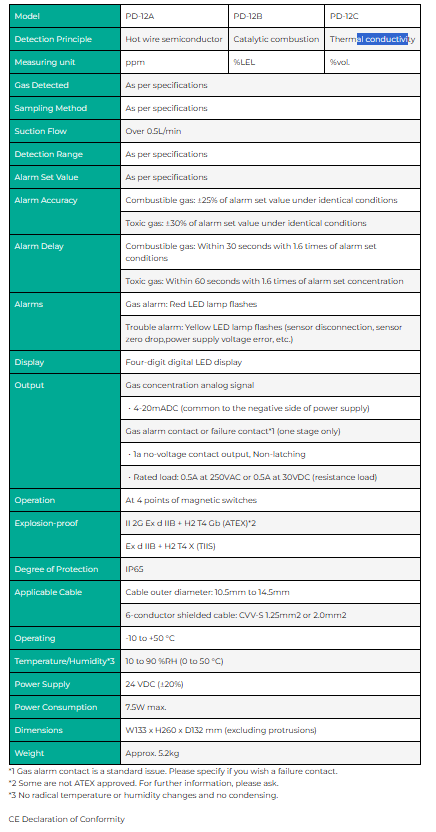

PD-12 ATEX Series Combustible Gas Detector

PD-12 type gas detector

A suction type ATEX detector with a very strong design. Suitable to detect a wide range of flammable and toxic gases in industrial applications and locations with limited access.

A unique detector in an ATEX enclosure with built in pump.

There are 3 models available:

- PD-12A for measurement of combustible gases in ppm range

- PD-12B for measurement of combustible gases in %LEL range

- PD-12C for measurement of combustible gases in %vol. range

Also available as SIL 1 version.

- Small and lightweight with concentration and alarm display

- Extractive type with hydrogen explosion proof (Ex d IIB + H2 T4X)

- Detecting decreased flow rate function except PD-12C (option)

- Environmental friendly product

- Water and dust-proof construction (Degree of protection: IP65)

Detectable gases:

- 1,1,1,3,3-Pentafluorobutane, C4H5F5

- Acetone, C3H6O

- Acetylene, C2H2

- Butane, C4H10

- Carbon dioxide, CO2

- Carbon monoxide, CO

- Cyclohexane, C6H12

- Ethanol, CH3CH2OH

- Ethylene, C2H4

- Gasoline, Benzin

- Helium, He

- Hydrogen, H2

- Isobutane, C4H10,

- Isopropyl alcohol, C3H8O

- Liquified Petroleum Gas, LPG

- Methane, CH4

- Methanol, CH4O

- n-Btane, C4H8

- Oxygen, O2

- Propane, C3H8

- Propylene, C3H6

Gas Detection Panel for Paint Shops

Gas monitoring panel for paint-shops.

Combustible and toxic gas detection solution with custom made integrated sample panel for paint-shop applications in the automotive industry.

Environment in a car manufacturing plant near the paint shop is very difficult to detect. Only when cooling, filtering and taking the moisture out of the gas sample will make sure that the gas detection will work in a proper way. The long history in this application and the unique product solution New Cosmos is offering makes that many car manufacturers use our gas detection panels near their paint shops

- Condensation of sample gas

- Avoid clogging of the sample tube by filtering

- Avoid sensor poisoning by solvents

- (Optional) Active cooling of target gas of up to 700 deegrees Celsius

- Autodrainer to collect access of moisture

- Tube drayer for final drying of the sample gas.

Detectable gases:

- Carbon monoxide, CO

- LNG

- Methane, CH4