Scrape Down Analysis (SDA)

Engine manufacturers have changed their engine design to comply with Tier IlI NOx regulations and the latest Energy Efficiency Design Index (EEDI) guidelines. As a result, cold corrosion in these engines is more likely to occur due to liner operation temperatures below the acid dew point. Older engines are nowadays forced to run on slow steaming mode to reduce fuel consumption.

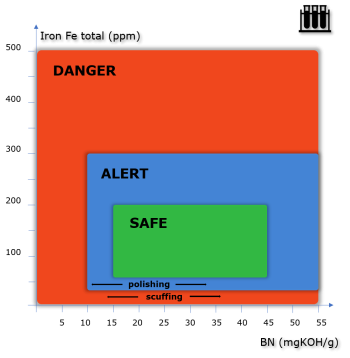

These engines now suffer similar problems with cold corrosion due to operation at lower temperatures. To identify a cold corrosion problem, a measuring tool is required to detect the total iron content in the scrape down oil. There are two different iron types existng – Corrosive (from Cold Corrosion) and Abrasive (Ferrous). The TriboIron 2.0 Test enables the ship operator to identify both types of iron.

As per engine manufactures 200 ppm iron content is a line.

Using TriboIron 2.0 you can:

-

- Get onboard fast, an indication for iron content from scraped oil,

- Understand conditions of the engine and

- Proceed to preventive and if necessary corrective actions.

- TriboIron 2.0 Test kit combined with TriboCon Mk III, that detects Base Number (BN) and optional Water in Oil (WiO), covers the whole Scrape Down Analysis (SDA).

Scrape Down Analysis (SDA) test kit

TriboIron 2.0 & TriboCon Mk III, BN test cases

Test Kit to check main parameters of your lube oil:

-

- Both Abrasive / Ferrous and Corrosive Iron (i.e. Total Iron) determination

- Base Number (BN) Test – alkalinity reserve of engine oils

- Viscosity Test – comparison of fresh and used oil

- Optional: Water in Oil (WiO)

The SDA oil test kit contains in addition to TriboIron 2.0 the two main tests – base number and viscosity – to determine the quality of lubricants onsite.

With TRIBOMAR products at your side you get the expertise to help yourself controlling the operational conditions of your machinery equipment.The new developed oil test case contains the test devices which enables engineers to test the most important parameters. This means a reliable indication about the performance of the engine oil at any time without a professional lab aside. Improved features on testing and handling are providing to the field engineer an easy to use test equipment with repeatable accuracy.

Order No.:

-

- #1638, Scrape Down Analysis (SDA) test kit. (incl. 60 Iron tests and 80 BN tests)

- #3125, Scrape Down Analysis (SDA) test kit. (incl. 60 Iron tests, 40 BN tests, 40 WiO tests and ViscoCheck)

Consumables:

Note: TriboIron 2.0 test cases and TriboCon Mk II test cases can be sold individually. See below.

Scrape Down Analysis (SDA) test kit

TriboIron 2.0 & TriboCon Mk II, BN test cases

Test Kit to check main parameters of your lube oil:

-

- Both Abrasive / Ferrous and Corrosive Iron (i.e. Total Iron) determination

- Base Number (BN) Test – alkalinity reserve of engine oils

- Viscosity Test – comparison of fresh and used oil

- Optional: Water in Oil (WiO)

The SDA oil test kit contains in addition to TriboIron 2.0 the two main tests – base number and viscosity – to determine the quality of lubricants onsite.

With TRIBOMAR products at your side you get the expertise to help yourself controlling the operational conditions of your machinery equipment.The new developed oil test case contains the test devices which enables engineers to test the most important parameters. This means a reliable indication about the performance of the engine oil at any time without a professional lab aside. Improved features on testing and handling are providing to the field engineer an easy to use test equipment with repeatable accuracy.

Order No.:

-

- #1638, Scrape Down Analysis (SDA) test kit. (incl. 60 Iron tests and 80 BN tests)

- #3125, Scrape Down Analysis (SDA) test kit. (incl. 60 Iron tests, 40 BN tests, 40 WiO tests and ViscoCheck)

Note: TriboIron 2.0 test cases and TriboCon Mk III test cases can be sold individually. See below.

TriboIron 2.0 (3rd Generation), Video of Operation (Iron test)

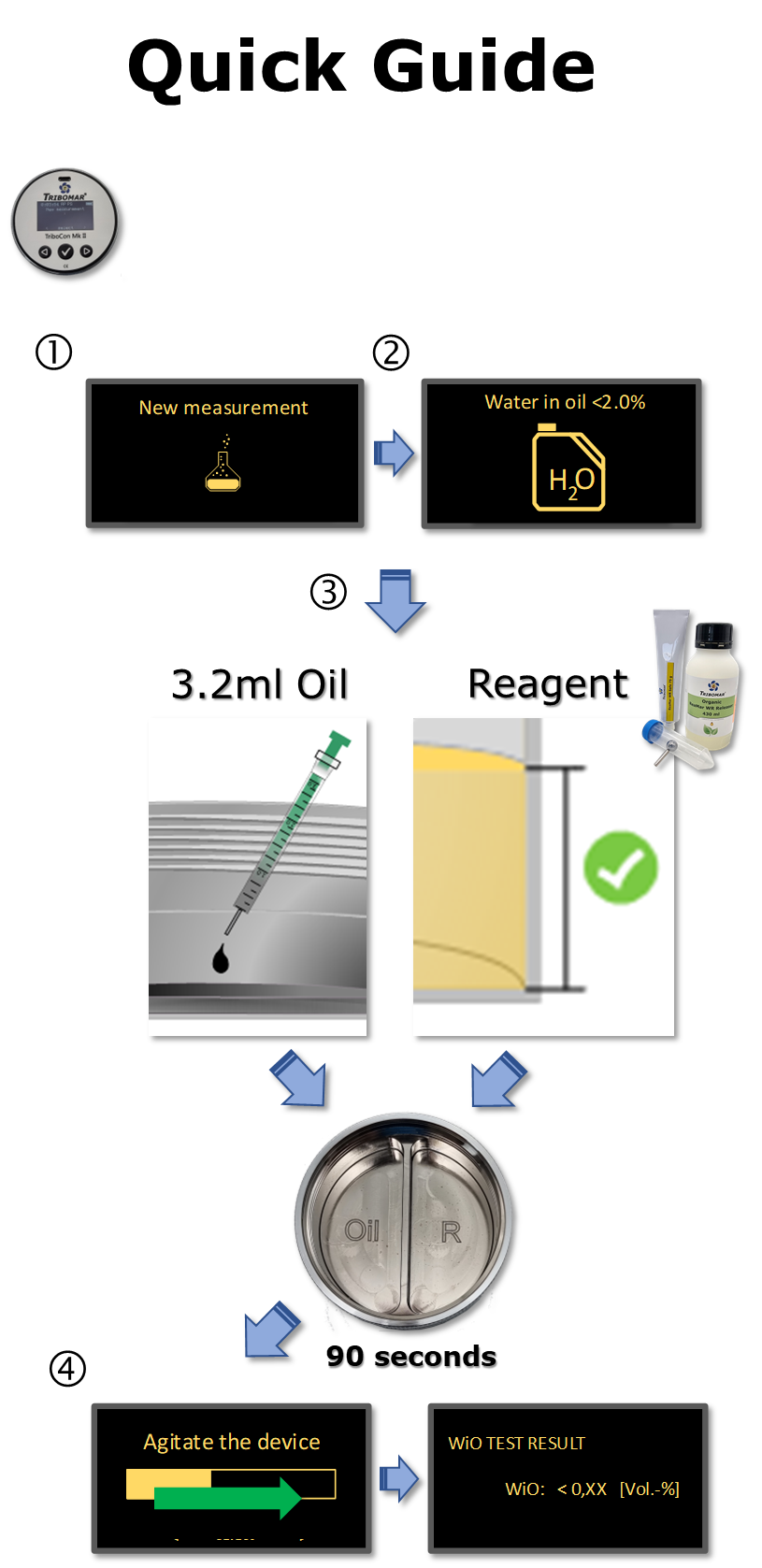

TriboCon Mk III, Video of Operation (Water in Oil test)

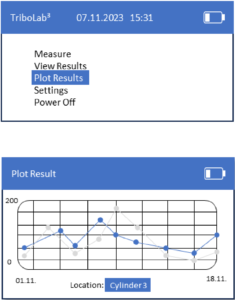

Digital Vortex Mixer with Timer

This mixer is a digital IR vortex mixer, operating in continuous or infrared system (IR) mode, with adjustable stirring speed up to 3.000 rpm. Thanks to the revolutionary IR sensor mode, an infrared system (IR) detects the presence of the test tube and the instrument automatically starts vibrating! No pressure is applied when using with IR Sensor mode. Through the timer, it is possible to set the operating time (up to 999:59 min.).

Ideal combination with TriboIron 2.0 Test Kit to get stable and repeatable results without user error influence.

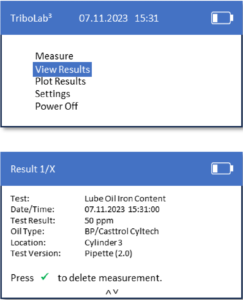

TriboIron 2.0, Iron Test Kit (3rd Generation)

- Abrasive / Ferrous & Corrosive Iron detection

- Total Measuring range: 0–600 / 2.500 ppm* (3rd Generation New feature)

- Corrosive iron: 0–600 / 2.500 ppm* (3rd Generation New feature)

- Abrasive/Ferrous iron: 0–600 / 2.500 ppm* (3rd Generation New feature)

- * depending on lube oil up to 2.500 ppm

- Accuracy: +/- 10%

- Test Kit includes 60 tests

- Non-dangerous consumables

- Lowest pollution from waste

- Automatic shaker available

- 1 test pill

- Automatic pipette

- Simple handling due to use of automatic pipette and test pills

- Measuring Time: 12 cylinders < 30min.

- Measuring Steps: 10ppm (TriboIron 2.0 can also be used to assume the wear of 4-stroke engines)

- All necessary consumables included

- Very easy to use – no errors possible

- Fast testing

- 17 different lube oil + 1 general available (3rd Generation New feature)

- Improved High Contrast Display (3rd Generation New feature)

- View Results (3rd Generation New feature)

- Plot Results for all Cylinders, for easy value comparison (3rd Generation New feature)

- Extract Results & Send via email (3rd Generation New feature)

- Rechargeable Batteries, connection via USB C to PC or charger (3rd Generation New Feature)

Order No.:

-

- #1505, TriboIron 2.0 Test Kit (incl. 60 Iron tests)

- #1506, TriboIron 2.0 Test Kit with Shaker (incl. 60 Iron tests)

Consumables:

TriboCon Mk III, Digital BN and Water in Oil (WiO) Test Kit

-

- Base Number (BN) Test – alkalinity reserve of engine oils

- Range: 4 – 150 mgKOH/g (BN)

- Pressure build up methodology

- Test time: 2 min

- Test Kit includes 80 BN tests (or 40 BN and 40 WiO tests)

- Non-dangerous consumables

- Robust coated metal housing

- Rechargeable Batteries

- 100 storage locations for test results

- Less errors by crew members possible

- Less time for the procedure

- Less waste on board

- Less prices for the device and reagents

- Can be used for Water-in-Oil Test for lubricants and fuels

- WiO Range: 0-10% (with additional WiO reagent, not included to SDA package #1638, included to #1016)

- Viscosity Test – comparison of fresh and used Oil

Order No.:

-

- #1615, Oil Test Case BN MkII (80 BN tests)

- #1016, Oil Test Case N°3 (40 BN tests, 40 WiO tests and ViscoCheck)

- #1068, Oil Test Case N°5 (40 BN test, 40 WiO tests, ViscoCheck, Isolubles / Impurities test and Salt test)

Consumables: